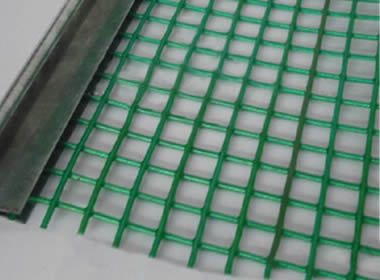

Steel Core Polyurethane Screen - Self-cleaning Performance

Steel core polyurethane screen is made of steel wire inside and polyurethane outside, which has high tensile strength and outstanding wear resistance. The steel core wires are welded into square or rectangular meshes. It has smooth surface and self-cleaning performance, so that it can avoid pegging or blinding.

The polyurethane colors can be various, such as red, orange, green, yellow, black. The various colors make the steel core polyurethane screen mesh be much more beautiful and can fit different vibrating screens.

Compared with modular polyurethane screen mesh, the steel core polyurethane screen mesh is flexible and soft. It has tensioned hooks which can be metal or polyurethane. The tensioned hooks can help the screen to be fastened to the vibrating screens easily.

Specifications

- Material: steel wire inside and polyurethane outside.

- Wire diameter: 2.5mm - 5mm.

- Hole type: square or rectangular.

- Hole size: 2mm - 25mm.

- Panel size:

- Width: max. 1.6m.

- Length: max. 2.85m.

- Hook type: metal or polyurethane.

Red steel core polyurethane screen.

Orange steel core polyurethane screen

Yellow steel core polyurethane screen.

Green steel core polyurethane screen.

Metal hook steel core polyurethane screen.

Polyurethane hook steel core polyurethane screen.

Features

- No pegging or blinding.

- Wear resistance.

- High tensile strength.

- High screening or separating efficiency.

- Lightweight and easy to install and remove.

- Low noise in the operation.

- Hook connection for easy fastening.

Applications

- Steel core polyurethane screen is ideal for various materials no matter wet or dry materials.

- The different sizes of steel core polyurethane screen can fit various vibrating screens.

- Steel core polyurethane screen can be used combined with woven vibrating screen mesh and modular polyurethane screen for different requirements.